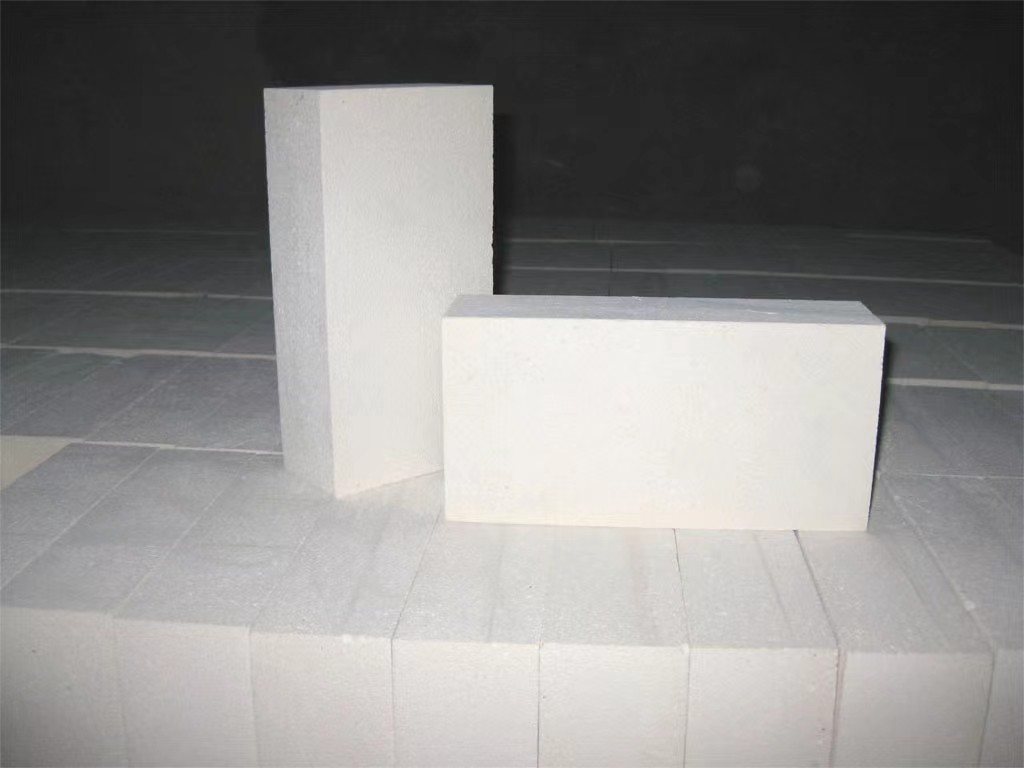

refractory bricks

During the discharge of products from a submerged arc furnace, high-temperature products flow out of the outlet in an environment with air, leading to oxidation, erosion, erosion, and deformation of the furnace door material, resulting in damage. In view of the defects and deficiencies such as inconvenient construction of the submerged arc furnace outlet, poor high temperature resistance, erosion resistance, corrosion resistance, poor oxidation resistance, short service life, etc., the company has developed a series of new submerged arc furnace door materials, which have good high temperature chemical stability, chemical erosion resistance and slag erosion resistance; Small coefficient of thermal expansion, anti deformation; High strength, high hardness, and erosion resistance; Good oxidation resistance, thermal shock resistance, and wear resistance; It has the advantages of long service life and convenient construction, making it an ideal material for the outlet of submerged arc furnaces.

At present, the company has obtained 5 national utility model patents for furnace door materials used in submerged arc furnaces such as calcium carbide furnace outlet and silicon calcium smelting furnace outlet. With research and practice in the field of submerged arc furnaces, the company can provide customers with personalized product customization and design solutions.

Hanjiang Hongyuan Xiangyang Silicon Carbide Special Ceramics Co., Ltd

- Phone: +86 0710-3155080

- Business Type: Manufacturer

- Location: China

- Main Products: silicon carbide Industrial ceramics Petroleum coke

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:South America,Asia,Europe

- Total Annual Revenue: