Sensor MTL-3

The principle of MTL3-EX explosion-proof magnetostrictive displacement sensor is to generate a strain pulse signal when two different magnetic fields intersect, and then calculate the time period required for this signal to be detected, thereby converting the accurate position. One of the two magnetic fields comes from the permanent magnet in the magnetic ring, and the other comes from the excitation pulses generated by the electronic components in the sensor electronics compartment. The excitation pulse runs at the speed of sound along the waveguide filament made of magnetostrictive material in the sensor. When intersecting with the permanent magnetic field in the magnetic ring, the mechanical vibration generated by the waveguide filament forms a strain pulse due to the magnetostriction phenomenon. The strain pulse is quickly detected by the sensing circuit in the electronic warehouse. The total time from the moment the excitation pulse is generated to the detection of the strain pulse is multiplied by the fixed speed of sound, and we can accurately calculate the change in the position of the magnet. This process is continuous, so whenever the position of the magnetic ring changes, the new position will be measured quickly. Since the output signal of the MTL3 reinforced sealed magnetostrictive displacement sensor is the real position value, rather than the proportional signal or the signal that needs to be re-amplified, there is no signal drift or value change, not to mention the need for regular repetition like other sensors. Mark.

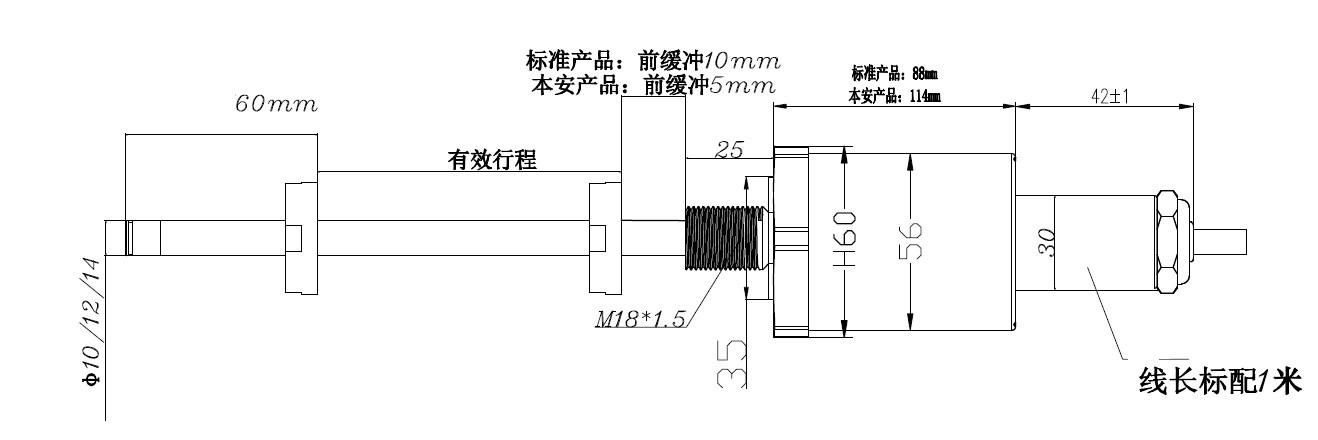

The MTL3-EX explosion-proof type is a series of magnetostrictive displacement sensors with built-in universal cylinders, with an effective stroke of 30mm~5000mm, and the buffer stroke at both ends can be customized according to customer needs. The electronic warehouse part can be disassembled for easy installation, and the head has an LED indicator light that can directly reflect the working status of the product. Various output signals, built-in imported waveguide wire as a measuring unit, processed by DSP digital signal, high precision, no temperature drift, no contact, life of up to 20 years; the measuring rod is resistant to high temperature and corrosion, and the pressure can reach 35MPa. It is suitable for most cylinder displacement measurement applications.

The principle of the MTL3 magnetostrictive displacement sensor is to generate a strain pulse signal when two different magnetic fields intersect, and then calculate the time period required for this signal to be detected, thereby converting the accurate position. One of the two magnetic fields comes from the permanent magnet in the magnetic ring, and the other comes from the excitation pulses generated by the electronic components in the sensor electronics compartment. The excitation pulse runs at the speed of sound along the waveguide filament made of magnetostrictive material in the sensor. When intersecting with the permanent magnetic field in the magnetic ring, the mechanical vibration generated by the waveguide filament forms a strain pulse due to the magnetostriction phenomenon. The strain pulse is quickly detected by the sensing circuit in the electronic warehouse. The total time from the moment the excitation pulse is generated to the detection of the strain pulse is multiplied by the fixed speed of sound, and we can accurately calculate the change in the position of the magnet. This process is continuous, so whenever the position of the magnetic ring changes, the new position will be measured quickly. Since the output signal of the MTL3 reinforced sealed magnetostrictive displacement sensor is the real position value, rather than the proportional signal or the signal that needs to be re-amplified, there is no signal drift or value change, not to mention the need for regular repetition like other sensors. Mark.

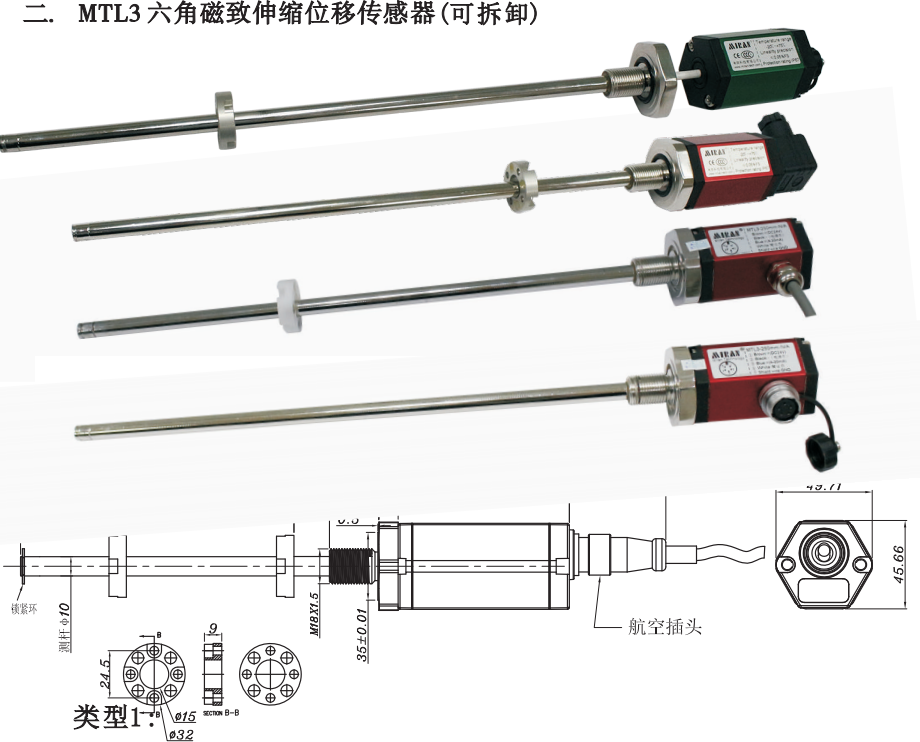

MTL3 is a series of built-in magnetostrictive displacement sensors for general-purpose cylinders, with an effective stroke of 30mm~5000mm, and the buffer stroke at both ends can be customized according to customer needs. The electronic warehouse part can be disassembled for easy installation, and the head has an LED indicator light that can directly reflect the working status of the product. Various output signals, built-in imported waveguide wire as the measuring unit, processed by DSP digital signal, high precision, no temperature drift, no contact, life of up to 20 years; the measuring rod is resistant to high temperature and corrosion, and the pressure can reach 64MPa. It is suitable for most cylinder displacement measurement applications.

Note: The current output type electronic warehouse is red, the voltage output type electronic warehouse is green, and the RS485 output type electronic warehouse is blue.

Xiangyang Haite measurement and Control Technology Co., Ltd

- Phone: +86 0710-3224206

- Business Type: Trading Company

- Location: China

- Main Products: track gauge ruler sensor railway ruler

- Total Employees:Less than 100 people

- Year Established:2017

- Export Markets:Domestic Market,North America,South America,Asia,Europe,Africa,Oceania

- Total Annual Revenue: